Description

Instructions for a correct working of cutter bars installed on articulated arms.

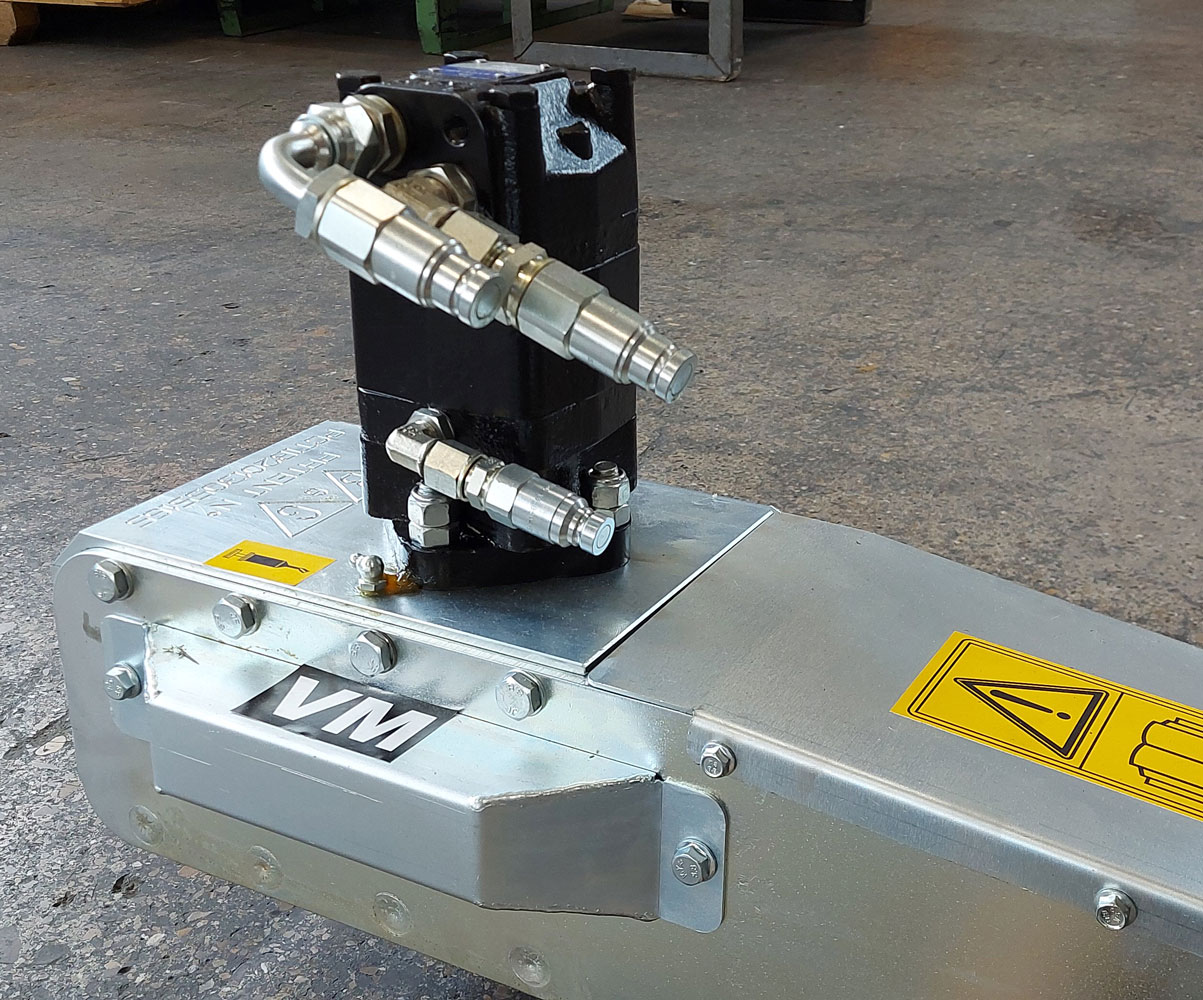

Double blade cutting bars – Medium version with hydraulic motor

For a correct working of cutter bars installed on articulated arms it is mandatory to respect the following rules:

- The articulated arm must carry the bar weight indicated in the brochure;

- The auxiliary plant oil capacity must respect what indicated in the brochure, for example “from 45 to 65 litres per minute”;

- VERY IMPORTANT: you must have a single-acting auxiliary plant;

- Mini excavators have a tap where it is possible to select the single-acting option (indicated with a hammer);

- To connect the bar motor you need to have three pipe lines: a first pipe for oil entrance, a second one for oil escape and a third pipe which is used for the motor drainage and must be free at discharge point; to do that it must be connected directly to the oil tank or you can use a tee joined with oil escape pipe near to the quick coupling attachment.

- Do not use agricultural quick couplings, only use industrial flat face quick couplings;

- It is recommended to have an oil cooler;

- Important: our models medium version, light version and super light version preview a third pipe installation for external hydraulic motor drainage, this solution reduces the damage to the motor oil seal and assures a longer life;

- We do not recommend the use of a motor with internal drainage;

- The maximum working pressure is between 150 and 170 bars.

Valves to be used for a correct cutter bar working:

Since we do not know the various hydraulic systems that our customers have we would like to give you some detailed information about the choice of valves to be used to obtain cutter bar best performance:

- Unidirectional valve for double acting systems

This valve must be previewed when confirming your order if your hydraulic installation is not a single-acting one, open centre or free discharge. It avoids the cutter bar motor oil seal to break.

- Oil capacity regulating valve

This valve must be previewed when confirming your order if the hydraulic installation has an oil capacity superior than the cutter bar requirement (please see bar characteristics in the brochure). Check your articulated arm manual to see which is its oil capacity.

- Shockproof maximum pressure valve

This valve must be previewed when ordering your bar if your hydraulic installation pressure is superior than 230 bars. Important: communicate and check the pressure indcated in the articulated arm manual.

CHARACTERISTICS

| Characteristics | Unit of measure |

| Cutter bar lenght and weight | 3000 mm (9.8 ft) – 300 kg (661 lb)

2500 mm (8.2ft) – 270 kg (595 lb) 2100 mm (6.9ft) – 240 kg (529 lb) 1700 mm (5.6ft) – 210 kg (463 lb) 1250 mm (4.1ft) – 180 kg (397 lb) |

| Revolutions per minute | 200 – 240 |

| Minimum / maximum cutting diameter | 0/60 mm – (0/2.4 in) |

| Knife width | 151 mm – (5.9 in) |

| Minimum / maximum discharge pressure | 200 – 230 bars |

| Best oil flow | Minimum 50 litres per minute |

| Packing measures to ship the articles in a wooden cage or box | Cutter bar 3000 mm (9.8 ft) wooden box or cage:

lenght 3500 mm (137.79 in) x width 800 mm (31.49 in) x height 600 mm (23.62 in) Cutter bar 2500 mm (8.2 ft) wooden box or cage: lenght 3000 mm (118.11 in) x width 800 mm (31.49 in) x height 600 mm (23.62 in) Cutter bar 2100 mm (6.9 ft) wooden box or cage: lenght 2600 mm (102.36) x width 800 mm (31.49 in) x height 600 mm (23.62 in) Cutter bar 1700 mm (5.6 ft) wooden box or cage: lenght 2200 mm (86.61 in) x width 800 mm (31.49 in) x height 600 mm (23.62 in) Cutter bar 1250 mm (4.1 ft) wooden box or cage: lenght 1750 mm (68.89 in) x width 800 mm (31.49 in) x height 600 mm (23.62 in)

|