Description

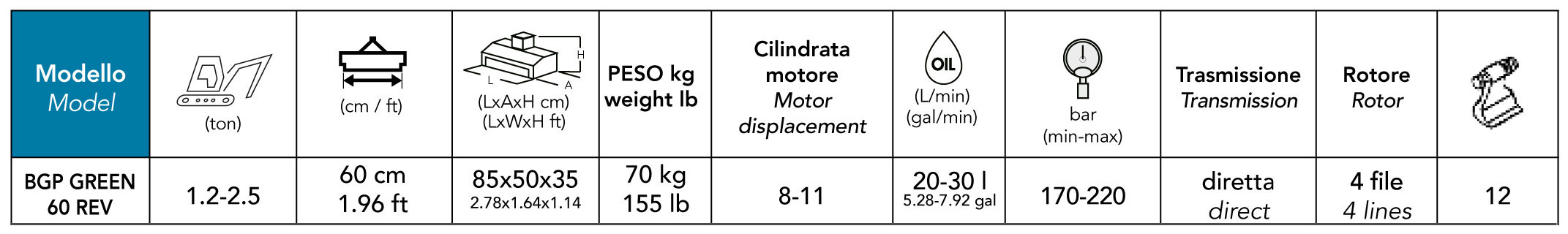

General Characteristics

- Direct transmission;

- Internally reinforced with double metal sheet;

- Shearing symmetric head, for a faster cut with the rotation of the excavator;

- Input and output mouths completely identical;

- Protective cover for motor;

- 4 Line Rotor with austempered blade M1F;

- Inside rotor supports with ”labyrinth” for the protection of the bearings from the impurities;

- Double row spherical adjustable bearings of 1st quality;

- Valves block complete with priority valve for adjusting oil flow, anti-shock valve (pressure relief valve), anti-cavitation;

- Gear motor;

- Accident prevention rubber protections according to EC directives.

Choose your cutting head with (standard equipment) HAMMERS or BLADES:

Instructions for a correct working of cutting heads installed on articulated arms.

For a correct working of cutting heads installed on articulated arms it is mandatory to respect the following rules:

- The articulated arm must carry the cutting head weight indicated in the brochure;

- The auxiliary plant oil capacity must respect what indicated in the brochure, for example “from 20 to 30 litres (5.28 – 7.92 gal) per minute”;

- VERY IMPORTANT: you must have a single-acting auxiliary plant;

- Most articulated arms have a tap allowing you to select the single-acting option (indicated with a hammer) or the double-acting one (indicated with a jack or with an auger). Always select the single-acting option, otherwise you will have to modify the hydraulic installation;

- Important: our cutting heads preview a valve block installation including a priority valve used to regulate oil capacity, a shockproof maximum pressure valve and an anti-cavitation valve which reduces the damage to the motor oil seal and assures a longer life;

- To connect the cutting head motor you need to have two pipe lines: a first pipe for oil entrance and a second one for oil escape (this pipe must be free at discharge point). If your hydraulic installation has a third free discharge pipe for motor drainage, the cutting head can be connected as well.

- Do not use agricultural quick couplings, only use industrial flat face quick couplings;

- It is recommended to have an oil cooler;

- We do not recommend the use of a motor with internal drainage;

- The maximum working pressure is 220 bars.

Valves used for a correct cutting head working:

Since we do not know the various hydraulic systems that our customers have we would like to give you some detailed information about the choice of valves to be used to obtain cutting head best performance:

- Standard unidirectional valve or anti-cavitation valve

This valve properly makes the rotor slow down when it is stopping, avoiding any counter-pressure. It also avoids the cutting head motor oli seal to break.

- Oil capacity regulating valve

This valve is used to reduce the installation oil capacity if it is superior than what is required for the cutting head (please see cutting head characteristics in the brochure). Check your articulated arm manual to see which is its oil capacity.

- Shockproof maximum pressure valve

This valve is activated if the installation pressure is superior than 220 bars. Important: communicate and check the pressure indcated in the articulated arm manual.